For more information on PCB, Leave your E-mail Address.

Introduction:

Express Delivery

24 hour turnaround time on double-sided PCB’s,

2-4 day turn available up to ten layers; over

ten layers can be done in one week. To shorten

the cycle time of new product introduction,

lower costs and take initial market share,

SENTAK is tailor made to satisfy your needs.

Advanced Technology Products

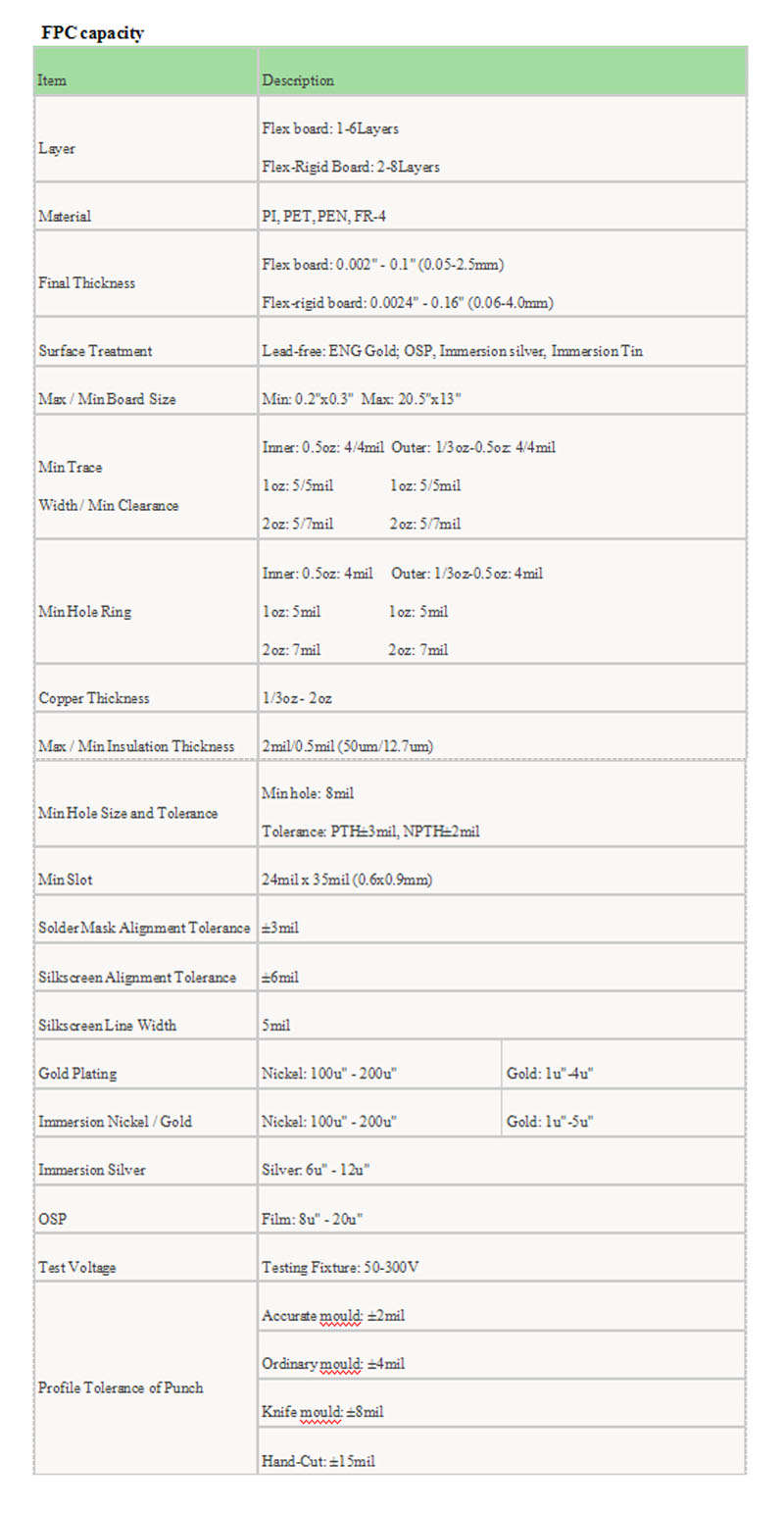

Backplanes, HDI boards, High-frequency boards,High TG boards, Halogen-free boards, Flexible and Rigid-Flex boards, Hybrids, and any boards with applications in high-tech products.

40 layers PCB, 2mil linewidth spacing

Our 20 years’ manufacturing experience, the use of Laser-direct Imaging,

laser drilling and contouring, high layer count lamination processing equipment,

pulse plating and other specialized equipment factory-wide enables Fastprint to

produce 40 layer and above rigid boards and rigid-flex circuits up to 20 layers.

Backplane thicknesses up to 0.276 (7mm), aspect ratios up to 30:1, 2/2 line/space

and impedance controlled designs are produced daily.

Partners

SENTAK has over 5000 domestic and international customers, including Huawei,

ZTE, Mindray and Omron in China; National Semiconductor, NVidia, Siemens Medical and over 50 more customers in the United States. Fastprint’s core competencies

of high mix, low-to-medium volume, high end and quickturn product, and flex/flex

rigid boards makes us an excellent fit from start-up to OEM.

Products and Technology Application

Providing a model for full-service manufacturing, SENTAK has a customer

base spread over 30 countries in Europe, the Americas and Asia. We use cutting-edge technology to provide time-critical product to communications, aerospace,

defense, IT, medical equipment, precision test equipment and industrial control

companies.

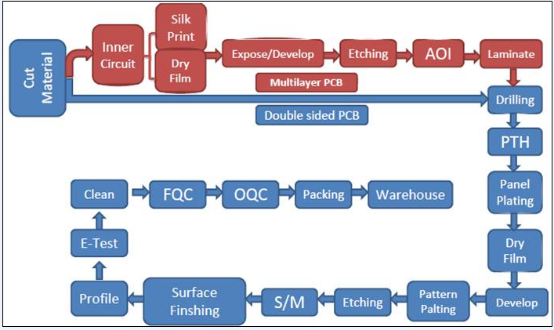

PCB

PRODUCTION PROCESS

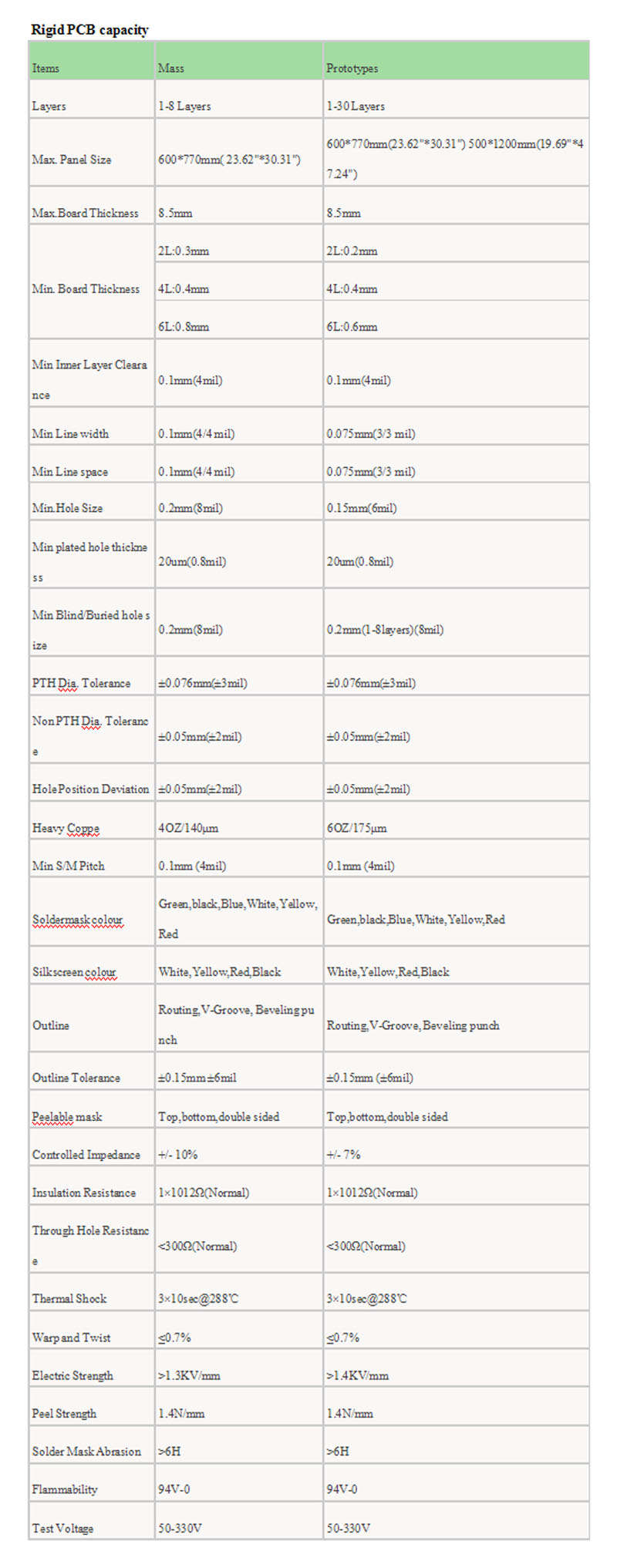

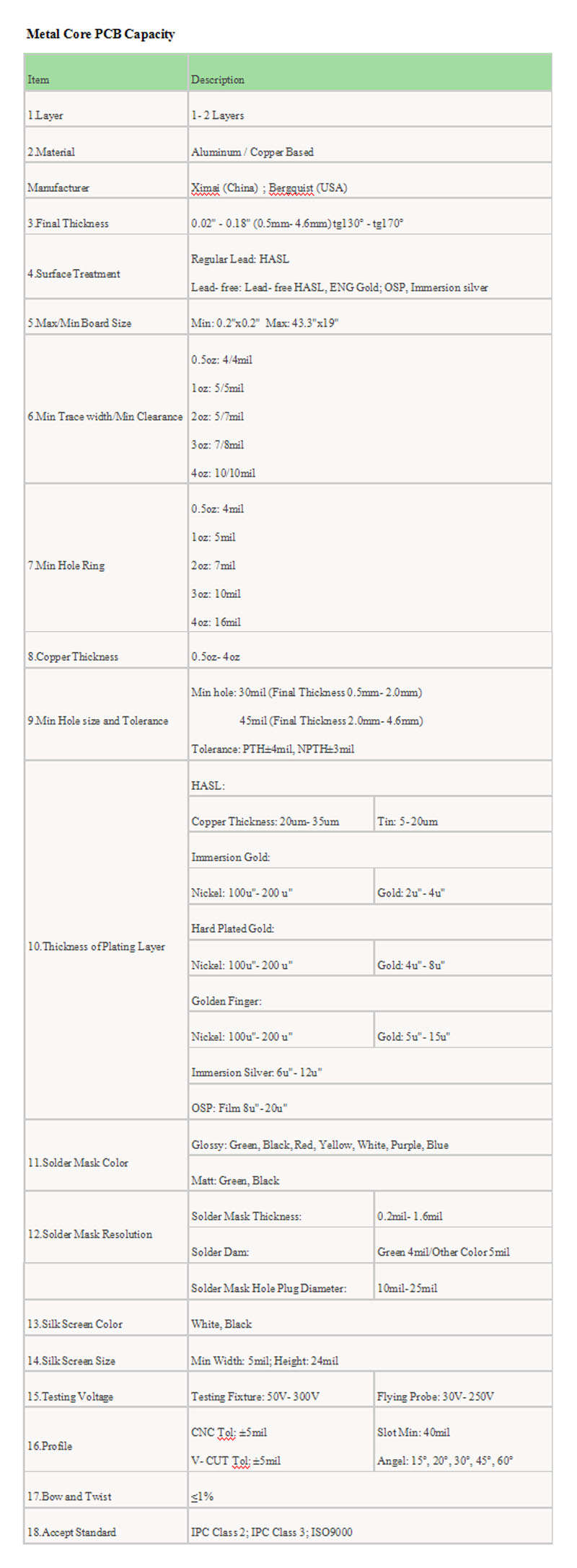

Capacity: